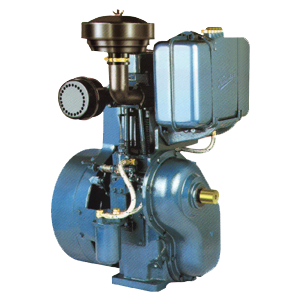

| Rating | 6-20Bhp @ 1500/1800 rpm |

| Cylinder | Single & Double |

| Application | Agriculture, Pumpset, Concrete Mixture, Thresher, Power Generation, Industries. |

| TA1/TA2 | TAF1 |  |  |

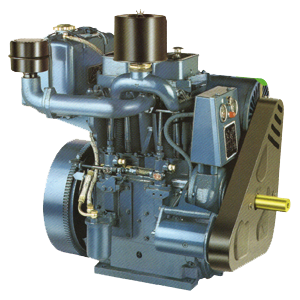

| Rating | 5-28Bhp @ 1500/1800rpm |

| Cylinder | Single & Double |

| Application | Agriculture, Pumpset, Concrete Mixture, Thresher, Power Generation, Industries,Sprinkler. |

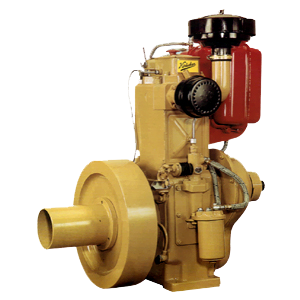

| SV1 | TV1/TV2 |  |  |

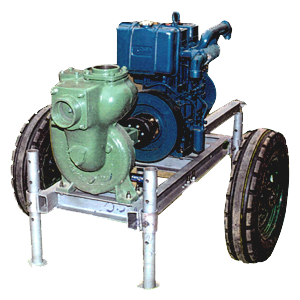

| AV1 | Slurry Pumpsets | ||

| Rating | 5-28Bhp @1500/1800rpmRating | 0.5-20Bhp @ 1500 rpm | |

| Application | Agriculture, Industries. | Application: | Industries. |

|  |

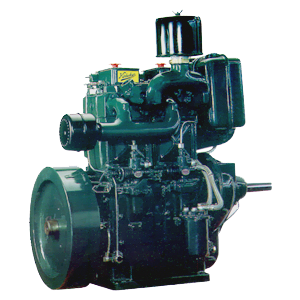

| Rating | 5-625Kva |

| Cooling | Water and Air |

| Application | Power Generation |

|  |

|

| FEATURES | VALUES/ STANDARDS |

|---|---|

| Ambient Temperature | -10 to +50°C |

| Altitude | Not exceeding 1000 m above mean sea level |

| Atmosphere | Non corrosive & non hazardous |

| Relative Humidity | Up to 100% |

| Voltage | 415V, 690V, 6.6kV, 3.3kV, 11kV +/- 10% |

| Frequency | 50Hz +/- 5% |

| Combined Variation | +/-10% |

| Duty | S1 (continuous) |

| Service factor | 1.0 |

| FEATURES | VALUES/ STANDARDS |

|---|---|

| Protection | IP 55 |

| Type of cooling | IC 611 / 616 / 8A1W7 |

| Class of Insulation | F / H |

| Terminal Box position | LHS from NDE |

| Bearing | Roller Bearings at NDE, Ball bearings at DE |

| Lubrication | Grease |

| Mounting | IM 1001, IM 3011, IM 2001, IM 3001 |

| Accessories | ACH, 6*simplex RTD, 2* Duplex RTD type BTD |

| Frame sizes | 355 frame to 710 frame |

| Shaft Extension | Single cylindrical extension as per IS:1231 |

| Connection | Star |

| FEATURES | VALUES/ STANDARDS |

|---|---|

| Method of starting | DOL |

| Vibration | As per IS: 12075 |

| Noise | As per IS: 12065 |

| Fault withstand level of Terminal Box | 43.7kA for 0.25sec, 39.4kA for 0.25 sec(in case of 11kV supply voltage) |

| Bearing Life | 40,000 working hours in case of direct drive. 20,000 working hours in case of belt drive. |

| RANGE | kW | FRAME SIZE |

|---|---|---|

| Small | 0.75 to 300 | 80 to 250 |

| Medium | 150 to 1500 | 280 to 630 |

| Large | 720 to 6500 | 710 to 1000 by centre height up to 3100 MM by rotor diameter |

| GENERAL SPECIFICATIONS | |

|---|---|

| Standards | BS 5000/IS 4722 |

| Insulation | CLASS F/CLASS H |

| Armature Voltage | 110 to 1000 volts |

| Field Voltage | 180 to 360 volts |

| Cooling | IC 01/06/0041/0666/W37A86/17/44 |

| Protection | IP 23/44/54 |

| Mounting | B3/B35/B5/V1/V5 |

| FRAME SIZE | OUTPUT IN | Max.Arm. Current | Max. Safe Speed | Excitation Power | Time Constant for Field Ckt. | Cooling Air Reqmt. | Moment of Inertia GD2 | |

|---|---|---|---|---|---|---|---|---|

| kW at 1500 RPM | (A) | (RPM) | (Watts) | (Secs) | VOL. (Lts/sec) | PR WG |

(kg M2) | |

| KLDC 100SX 100MX 100LX |

4.0 6.0 7.6 |

40 | 6000 6000 6000 |

350 450 600 |

0.08 0.08 0.10 |

50 | 35 | 0.100 0.132 0.164 |

| KLDC 112SX 112MX 112LX |

9.3 12.5 15.0 |

60 | 6000 6000 6000 |

750 900 1000 |

0.11 0.12 0.13 |

100 | 60 | 0.172 0.220 0.254 |

| KLDC 132SX 132MX 132LX |

18.75 25.00 28.00 |

105 | 5000 4800 4500 |

900 1000 1150 |

0.16 0.18 0.19 |

140 | 90 | 0.508 0.556 0.600 |

| KLDC 160KX 160SX 160MX 160LX |

30.00 37.00 45.00 56.00 |

240 | 4000 4000 4000 4000 |

900 950 1050 1150 |

0.24 0.26 0.28 0.30 |

290 | 100 | 0.72 0.96 1.08 1.40 |

| KLDC 180SX 180MX 180LX |

70.00 80.00 90.00 |

300 | 3750 3750 3500 |

1100 1250 1400 |

0.33 0.33 0.33 |

400 | 110 | 1.84 2.04 2.20 |

| KLDC 200SX 200MX 200LX |

110.00 130.00 150.00 |

385 | 3500 3500 3250 |

1450 1600 1850 |

0.43 0.43 0.43 |

510 | 135 | 3.24 3.64 4.28 |

| KLDC 225SX 225MX 225LX |

160.00 180.00 200.00 |

675 | 3000 3000 2600 |

1900 2100 2300 |

0.57 0.57 0.57 |

710 | 140 | 6.80 7.60 8.30 |

| KLDC 250SX 250MX 250LX |

235.00 260.00 300.00 |

750 | 2500 2500 2300 |

2350 2600 3000 |

0.71 0.71 0.71 |

850 | 150 | 11.6 13.2 15.8 |

| FRAME SIZE | OUTPUT IN kW at 1500RPM | SPEED (RPM) | Max.Arm. Current (A) | Max. Safe Speed (RPM) | Excitation Power (Watts) | Force Cooling Unit Details | Moment of Inertia GD2 (kg M2) |

|---|---|---|---|---|---|---|---|

| KLDC 280S 280M 280L |

265.00 330.00 400.00 |

1750 1750 1750 |

800 800 800 |

2300 2300 2300 |

2200 2650 3200 |

3.7kW, 415V, 3phase, 50Hz, 2pole |

19 24 28 |

| KLDC 315S 315M 315L |

320.00 400.00 460.00 |

1500 1500 1500 |

920 920 920 |

2000 2000 2000 |

2400 3000 3500 |

3.7kW, 415V, 3phase, 50Hz, 2pole |

30 40 55 |

| KLDC 355S 355M 355L |

380.00 500.00 600.00 |

1250 1250 1250 |

1100 1100 1100 |

1900 1900 1900 |

2500 3350 4000 |

5.5kW, 415V, 3phase, 50Hz, 2pole |

38 46 58 |

| KLDC 400S 400M 400L |

500.00 625.00 750.00 |

1000 1000 1000 |

1380 1380 1380 |

1700 1700 1700 |

3500 4400 5300 |

7.5kW, 415V, 3phase, 50Hz, 4pole |

100 125 150 |

| KLDC 450S 450M 450L |

615.00 740.00 875.00 |

750 750 750 |

1380 1380 1380 |

1600 1600 1600 |

4600 5500 6500 |

7.5kW, 415V, 3phase, 50Hz, 4pole |

145 175 230 |

| KLDC 500S 500M 500L |

635.00 790.00 950.00 |

750 750 750 |

1900 1900 1900 |

1400 1400 1400 |

4800 6000 7200 |

11kW, 415V, 3phase, 50Hz, 4pole |

285 325 370 |

| KLDC 560S 560M 560L |

750.00 900.00 1050.00 |

500 500 500 |

1900 1900 1900 |

1300 1300 1300 |

6400 7600 9000 |

11kW, 415V, 3phase, 50Hz, 4pole |

550 630 750 |

| KLDC 630S 630M 630L |

900.00 1150.00 1300.00 |

450 450 450 |

2100 2100 2100 |

1200 1200 1200 |

7400 9300 10500 |

15kW, 415V, 3phase, 50Hz, 4pole |

1020 1170 1370 |

| Particulars | |

|---|---|

| Phase |

Three/single |

| Frequency, Hz | 50 |

| Voltage, V | 415/240 |

| Power factor, lag | 0.8 |

| Ambient | 40°C |

| Altitude | 1000 mtrs |

| Speed, rpm | 1500 |

| Mounting | Horizontal foot mounted |

| Duty | Continuous |

| Direction of rotation | Clockwise from DE |

| Automatic voltage regulator | M/c mounted |

| Voltage regulation | +/-1% with 4% prime mover speed variation |

| Standards | IS 4722 -1992, IEC 34 |

| Class of insulation | H |

| Temperature rise | H |

| Enclosure | IP 20 |

| Cooling | IC 01 |

| Wave form distortion (thd) | Less than 3% |

| Overload capacity | 10% overload for 1 hour. once in 12 hours |

| Unbalance permitted | 25% with none of the phase currents exceeding the rated current. Temperature rise limits for corresponding class of insulation may exceed 10°C under such conditions. Voltage regulation under above condition will not apply. |

| No. of bearings | Single/double |

| Lubrication type | Grease lubricated |

160 KVA 11KV up to 10,000 KVA, 33 KV Class In addition to the above, we have the expertise Dealer & test cast resin dry type transformers for a client's special and stringent requirements to converter, rectifier, static excitation and other special applications as well

The cast resin dry type transformers are designed and tested to comply with national & international standards such as IS 11171, IEC 60726, ANSI, NEMA, and Australian Standard.